Sani-Tech® Ultra The Next Generation Tubing

Sani-Tech® Ultra represents the next generation in ultra-pure platinum-cured silicone

tubing. Quite simply, it’s a better product. Features like ultra-low extractables and longer

pump life were engineered into Ultra by the experienced materials scientists of Saint

Gobain Performance Plastics to meet the stringent requirements of the biopharmaceutical

market.

Applications

Sterile fill and transfers

Drug delivery

Cell harvest

Media processing

Sanitary peristaltic pump tubing

Production filtration and fermentation

Bioreactor process lines

Characteristics

Fluid integrity is vitally important in many biopharmaceutical applications. Sani-Tech® Ultra formulations are manufactured and packaged in a certified clean room from the finest grade of silicone materials. Ultra-low TOCs ensure that contamination by extractables is kept to an absolute minimum. Saint-Gobain Performance Plastics’ silicone tubing is known for its superior pump life — and Sani-Tech® Ultra is no exception. In all our multiple production sites (US, France, and India) our tubing are produced and double bag packaged in an ISO 7 clean room.

Biocompatibility

Sani-Tech® Ultra is manufactured from the finest grade of silicone materials and is fully characterized, validated and tested to a variety of specifications including USP Class VI, ISO 10993, and European Pharmacopoeia 3.1.9. For additional compliance data visit www. biopharm.saint-gobain.com to download Validation Guide and Regulatory Information Overview (RIO) or contact our customer service department. Sani-Tech® Ultra has a Drug Master File Type II with the U.S. Food and Drug Administration.

Features / Benefits

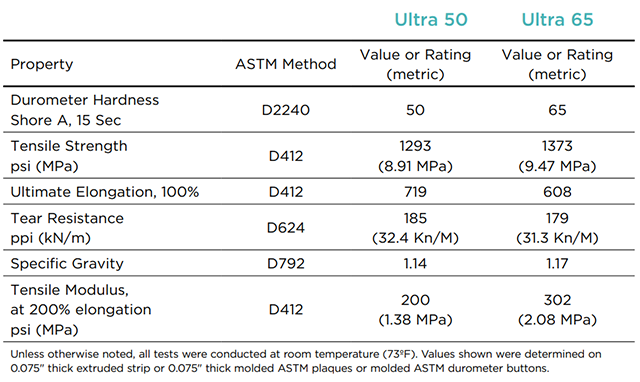

Two hardnesses available, 50 and 65 shore

Mulitple manufacturing sites: US, France, and India

Biopharmaceutical grade

Ultra-low extractables

Excellent flexibility

Laser etched for lot traceability

Superior pump life

Fully autoclavable and sterilizable

Non-yellowing formulation

Temperature range from -80°F (-62°C) to 500°F (260°C)

Meets USP Class VI, EP 3.1.9 and ISO 10993

Available in 25-, 50- and 100-foot coils

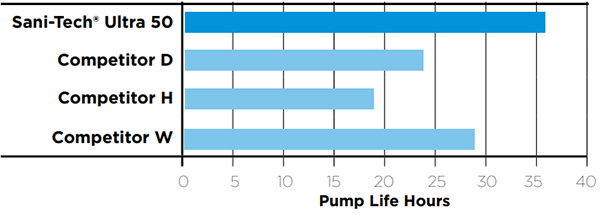

Comparative Peristaltic Pump Tubing Life

The table below depicts hours until failure of 1/4" ID x 3/8" OD tubing. In each case, a 3-roller pump head was utilized operating at 600 RPM at room temperature (73°F)

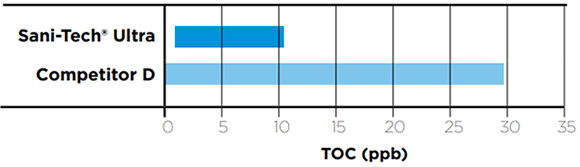

Comparative Extractables Concentrations

The table below illustrates the TOC concentrations of post autoclaved tubing samples. In each case the samples were subjected to a DI water flush and the effluent was analyzed.

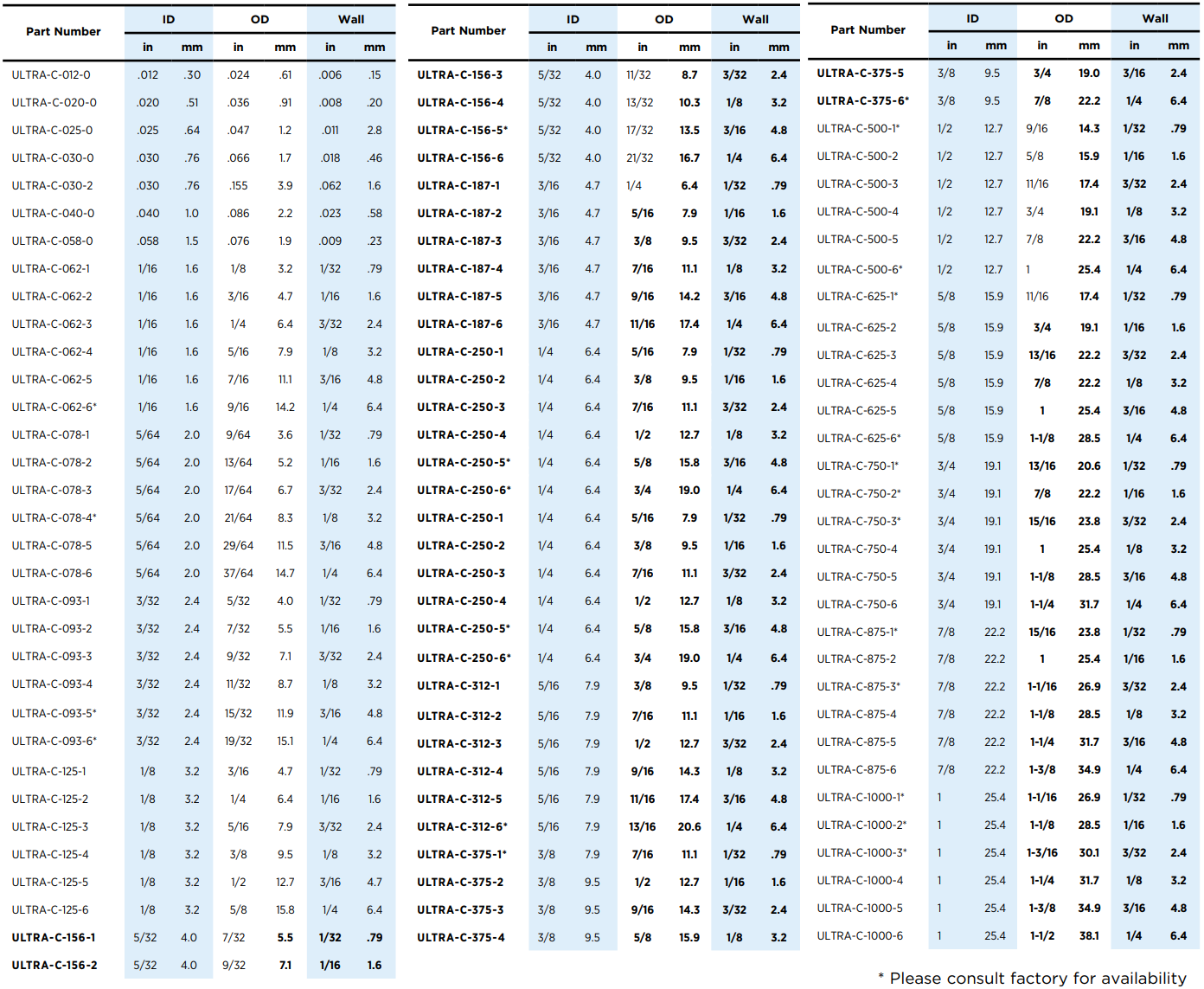

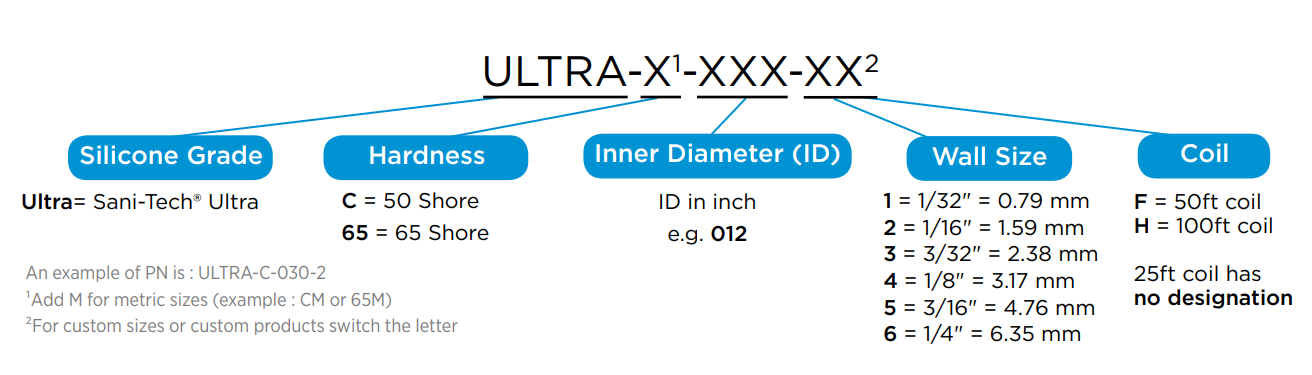

Sani-Tech® Ultra Tubing Available Sizes

Typical Physical Properties

Characterization

The bio-compatibility of Sani-Tech® Ultra platinum-cured silicone tubing, manufactured with Sani-Tech® silicone, has been tested and complies with the parameters set forth in the following test protocols:

USP Class VI (88) biological reactivity, in vivo - Intracutaneous test, Systemic injection test, Implantation test

USP 87 biological reactivity, in vitro - L929 MEM elution, AGAR diffusion

USP 381 elastomeric closure for injection

USP 85 endotoxin

European Pharmacopoeia 3.1.9

USP limits for total organic carbons

Gamma irradiation

Infrared analysis

ISO 10993

NOTE: Sani-Tech® Ultra tubing will not deteriorate with repeated autoclaving. This method of sterilization is strongly recommended. Sani-Tech® Ultra silicones should not be considered for consistent steam applications. WARNING: Do not use Sani-Tech® Ultra silicone tubing in hot oil or acid applications.

Sani-Tech® Ultra Options

Custom laylines

Gamma irradiated

Bulk spool packaging

Custom sizes available

Available in custom lengths and durometers

Sterilization Methods

Autoclavable

Gamma irradiation

Up to 5.0 Mrad (50 Kilogray)

Gas - ethylene oxide