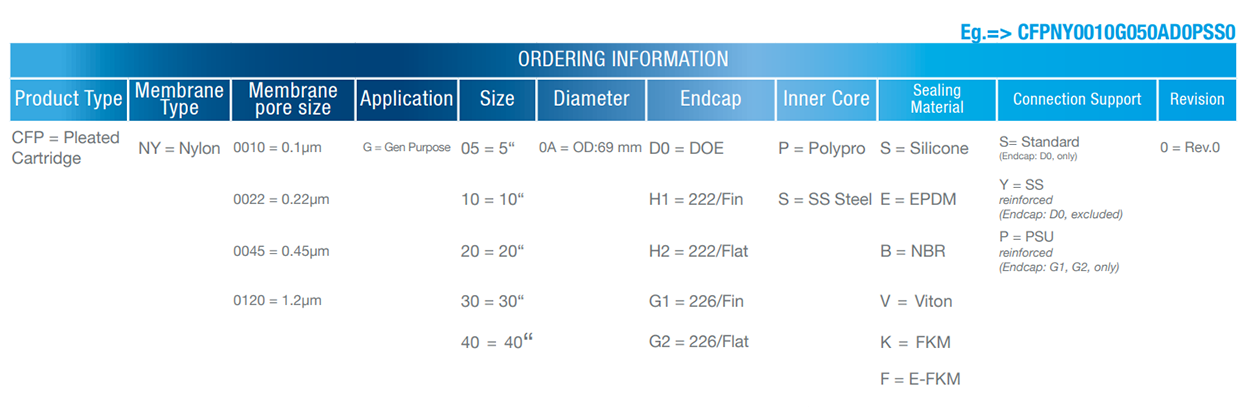

CFP series Nylon membrane General Applications NY Pleated Filter Cartridges

CFP series Nylon membrane General Applications Pleated Filter Cartridges are naturally hydrophillic due to polyamides filter media. This filter media has a high porosity and uniform pore size distribution, giving to series products high flow rate, high retention ability and long service life.

Applications

Large volume parenterals (LVP) injections and antibiotic filtration

Physiological saline solution and other solvents filtration of microorganism removal

Pure Water and water-based filtration of microorganism removal

Features

Naturally hydrophilic, no need for pre-wetting

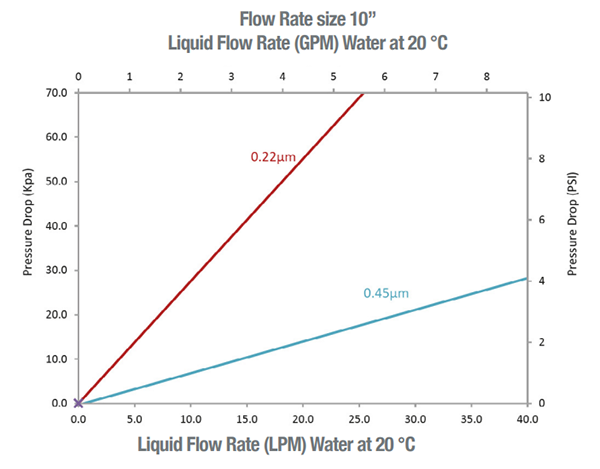

High flow rate, low DP and long service life

Excellent integrity provides good particle removal and sterilization efficiency

Non-contact welding adopted, no adhesives, low extractables

Excellent chemical compactivity

Tolerance for in-line steam sterilization

Gross integrity

Dimension

| Out Diameter | 2,72” (69 mm) |

|---|---|

| Length | 5” (125 mm), 10” (254 mm), 20” (500 mm), 30” (750 mm), 40” (1000 mm) |

Quality

Filter Cartridges are manufactured in a clean room environment

Manufactured according to ISO9001:2015 certified Quality Management System

Food Contact Compliance

Materials of construction comply with FDA regulations for food and beverage contact use as detailed in the US Code of Federal Regulations 21 CFR.

Materials used to produce filter media and hardware meet the specifications for biological safety per USP Calss VI-121C for plastics.

Filter cartridges passed European Commission Directives (EU10/2011)

Halal Certified

Material of Constructions

| Filter medium | Nylon N66 |

|---|---|

| Support/Drainage | PET |

| Cage/Core | Polypropylene |

| Endcap | Polypropylene and Insert |

Performance

| Max Operating Temperature | 80 °C |

|---|---|

| Max Operating DP | Forward 4.0 bar @ 25 °C, Forward 2.4 bar @ 80 °C |

| SIP | 125 °C , 30min |

Guarantees

Manufactured in 100,000-class clean room environment

Manufactured according to ISO9001:2015 certified quality management system

Meets USP Biological Reactivity Test Requirements of the current USP <88> for plastic class VI

Extractables per 10 inch < 25 mg